PRESSURE REDUCING STATION DESIGN GUIDELINES PRESSURE REDUCING STATION GENERAL SPECIFICATION I. Therefore it has been widely used in steam pressure reduction systems the.

Pin By Rao Fateh On Science Fire Protection System Safety Valve Fire Sprinkler System

They will require 30 PSIG at the station and the heating and domestic water system design require 10 PSIG steam.

. A properly designed PRV station should have correct selection of the components because every component is indispensable in the system. The total steam capacities must be equal to or greater than the maximum steam. Pressure Reducing Stations must be designed to allow for the maximum system turn down.

Office of Facilities CC. What is Steam Pressure Reduction. Most modern boilers operate at high pressures typically 105 to 175 kgcm2g.

All pressure reducing valve stations serving an entire building will have 2 pressure reducing valves sized at 13 and 23 of the total load. Reduce moisture particle entrainment to avoid erosion to valves and fittings. Hence a properly sized pressure reducing station PRS is required for efficient of steam with minimum losses.

Setting on the boiler plant master control. Reducing the likelihood of internal erosion and premature valve failure. Pressure reducing valves shall be selected and specified around a Spence Type E.

01 - Yale Design Standard Division. Noise With steam there can be several aerodynamic noise producing mechanisms including. Design and Flow Concept Page 5 from 7 September 2005 Diagram 1.

When to use single stage regulator. Pressure Reducing Stations or PRD stations are an integral part of any steam system. The set points are below the steam system maximum design pressure.

They reduce the pressure and hence the temperature of steam just before the process. New York Engineers under its prestigious reputation in Chicago guarantees to offer pressure reducing valves with long-lasting operational life of at least 6 years. Pressure Reducing Valves.

Bypass lines are not required. 8Steam at high pressure HP has a relatively higher. The autoclaves have a maximum pressure of 50 PSIG.

Within practical limits pressure-reducing valves PRVs will adjust the pressure at lower levels to the. Thermax Pressure Reducing Station TPRS is a prefabricated ready to assemble module comprises of control valves isolation valves pipes and fittings intended to reduce steam pressure to designed conditions. Gauge Steam Pressure 1 No 3 Strainer Removes dirt rust scale etc.

When only one reduced steam. Project Folder Page 1 of 10 PART 1 - INTRODUCTION 11 PURPOSE A. Initially this pressure depends on the nominal pressure of the section of the system dow nstream of the pressure reducing station and on the.

The correct design and component selection of steam pressure reducing valve stations will highly extend the operational life of the steam system. Pressure reducing Desuperheating station. Safety valve flanges will be installed according to the appropriate bolt torque.

When load turndown requirement is generally no greater than 101. Pressure reducer - for saturated steam With safety valves the first step is to define the set pressure. Good steam engineering practice is to generate steam at highmaximum working pressure distribute at higher pressure and utilize at low pressure with pressure reduction.

The design of the Main Steam Pressure Reducing Stations in buildings that are being supplied steam from a central steam generating plant or other high pressure steam generating source must take into consideration load characteristics rangeability noise safety reliability long- term maintenance costs and overall control performance. The Steam Pressure-Reducing Station SPRS Safety and Energy Efficiency Improvement Project which is under the CPI program focuses on maintaining and upgrading SPRSs that are part of the ORNL steam distribution network. For the most basic pressure reduction it is possible to simply use a conventional globe valve in a fixed partly-open position or.

Finally install a blow-off valve on the strainer to allow plant personnel to periodically clean out the strainer. Steam pressure reduction is the lowering of the steam pressure at the boiler plant by means of the pressure. SINGLE STAGE PRESSURE REGULATOR 1.

Using a self-operated steam pressure regulator as a steam pressure reducing station is simple and convenient with little maintenance costs and is especially suitable for on-site situations where there is no electricity and no air power. The drip trap for the PRVs requires a capacity with safety factors of 85 PPH. Now lets identify the steam PRVs and size the steam and drip trap condensate pipe.

This steam pipe network transports steam produced at the ORNL steam plant to many buildings in the main campus site. 1 Using a Steam Self-Operated Pressure Regulator. Design ensures that the total required.

Pressure reducing stations 2D CAD application drawings to help you plan and design your steam system. The Steam Pressure Reducing Station. Placing the steam PRV correctly in the station helps to ensure proper system operation.

Steam pressure reduction affects mainly the high pressure part of the steam system. Steam pressure reducing station is more than a control valve especially when steam varies greatly. When ratio of specific volume of steam outlet to inlet is no greater than 3 to 1.

It is recommended to operate the boilers close to maximum operatingdesign pressureThis ensures good quality of steam with high. It is sized using special software to ensure appropriate parameters as per design conditions. WHY IS STEAM GENERATED AT HIGH PRESSURE.

Reducing Steam Pressure A common way of lowering pressure is by throttling down the size of the steam passageway. Locate the pressure reducing valve sensing 5 pipe diameters 1. Most of the process industries need steam at different pressures for different applications.

About us Global Locations Careers Learn about steam Resources and Design Tools Contact Head Office. A steam pressure-reducing valve station often employs a pneumatic control valve or a regulating valvesometimes called a pressure-reducing valve as. The steam pressure-reducing valve station an indispensable part of a steam system.

This section is intended to define the general installation and minimum product requirements for Steam Pressure Reducing Valve Stations it is not inclusive to the control. Follow the Spence Regulator Designers guide for sizing and layout of PRV stations. This design has been incorporated with a high degree of reliable quality components for trouble-free service.

They will require 30 PSIG at the station and the heating and domestic water system design require 10 PSIG steam. It plays a critical role by providing the correct steam pressure to the process application in the process plant. Two Stage Pressure Reducing Valve Station with Safety Valve.

PRV station is usually prefabricated assembly which.

Pressure Reducing Stations Design Manufacture Supplier And Exporter Steam Boiler Water Generator Pressure

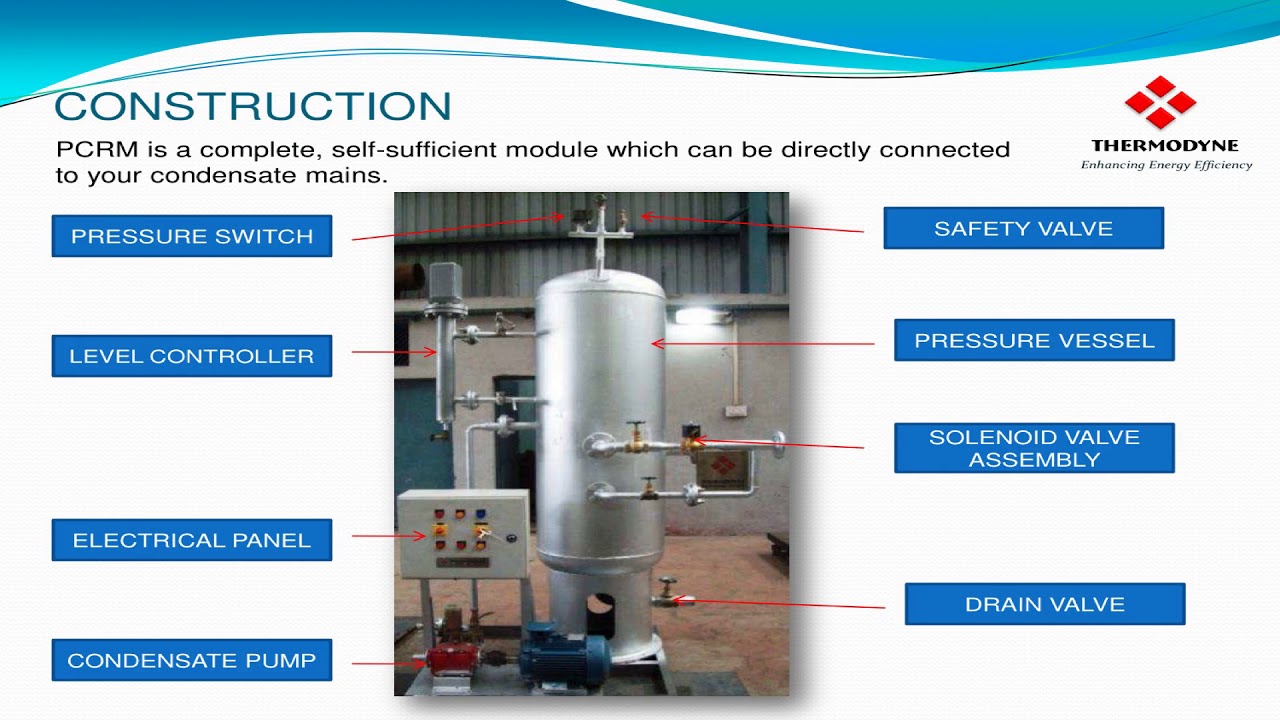

Condensate Recovery Systems Pcrm Condensate Recovery Electrical Panel System Recovery

Steam Pressure Reducing Station Pressure Inlet Valve Station

Direct Acting Pressure Regulator Valve On Steam System In Turkey Pressure Control Valve Valve Control Valves

Pilotgesteuerter Druckminderer Aus Edelstahl 304 Dn40 Dn50 Gewindeanschlussen Und Dn50 Dn350 Fur Flanschanschlussen Mehr Informatio Hydrant Fire Hydrant Fire

Pressure Regulators Pressure Control Valve Control Valves Valve

Pressure Reducing Stations Design Manufacture Supplier And Exporter Steam Boiler Water Generator Pressure

0 comments

Post a Comment